Guaranteed: sustainable quality,

certified performance and products

Quality and customer satisfaction

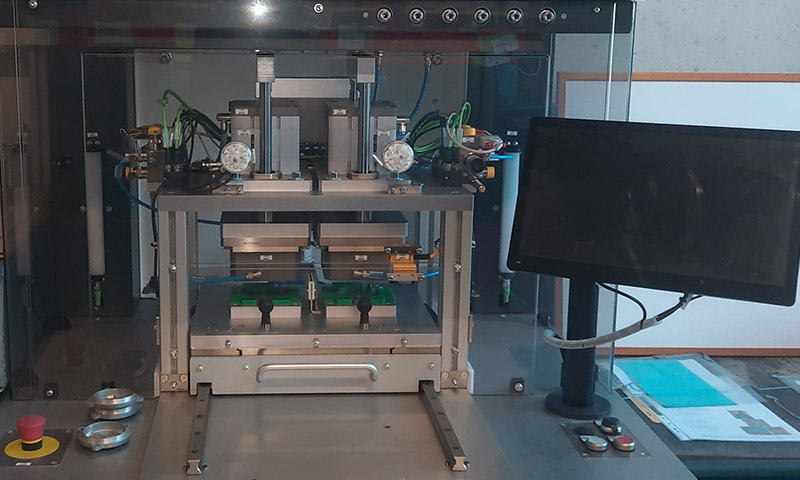

For the traditional company AMZ Weissenseer Präzisionsguss GmbH, customer satisfaction is our top priority. To this end, it is important to design the quality standards in all production processes and workflows in such a way that the high quality standard can be maintained and implemented sustainably. Quality begins with the development of the component and the design of the die casting tools. Our production-accompanying quality assurance is supported by the latest and state-of-the-art testing machines in order to detect components that are outside the customer’s specifications at an early stage.

Certifications

AMZ Weissenseer Präzisionsguss GmbH has been certified since 26.11.2009 by TÜV Rheinland Cert GmbH according to DIN EN ISO 9001:2015, certificate registration no. 01 100 6011.

For the scope of process development, production and salesready-to-install components and complete assemblies in the die casting process made of aluminum and zinc, the TÜV CERT certification body of TÜV Anlagentechnik GmbH confirms the introduction, application and maintenance of a quality management system.

AMZ Weissenseer Präzisionsguss GmbH was certified according to IATF 16949:2016 by TÜV Rheinland Cert GmbH from 26.11.2009 to 23.11.23. Due to the enormous expenses for the implementation of the IATF standard, which are economically out of proportion, AMZ Weissenseer Präzisionsguss GmbH has decided to have only DIN EN ISO 9001 certified in the future.

All quality standards from the IATF standard that have already been introduced will continue to apply.

As part of an audit by our customer AIRBUS in 2007, the successful application of a comprehensive quality management system for suppliers to the aerospace industry according to DIN EN 9100 was certified.

Quality assurance

With consistent quality management, AMZ Weissenseer Präzisionsguss GmbH has achieved a very high degree of quality assurance. For this reason, top-class customers were successfully served continuously. For example, from the demanding fields of X-ray technology, spectral analysis and 3D metrology.